Generalities about the flame

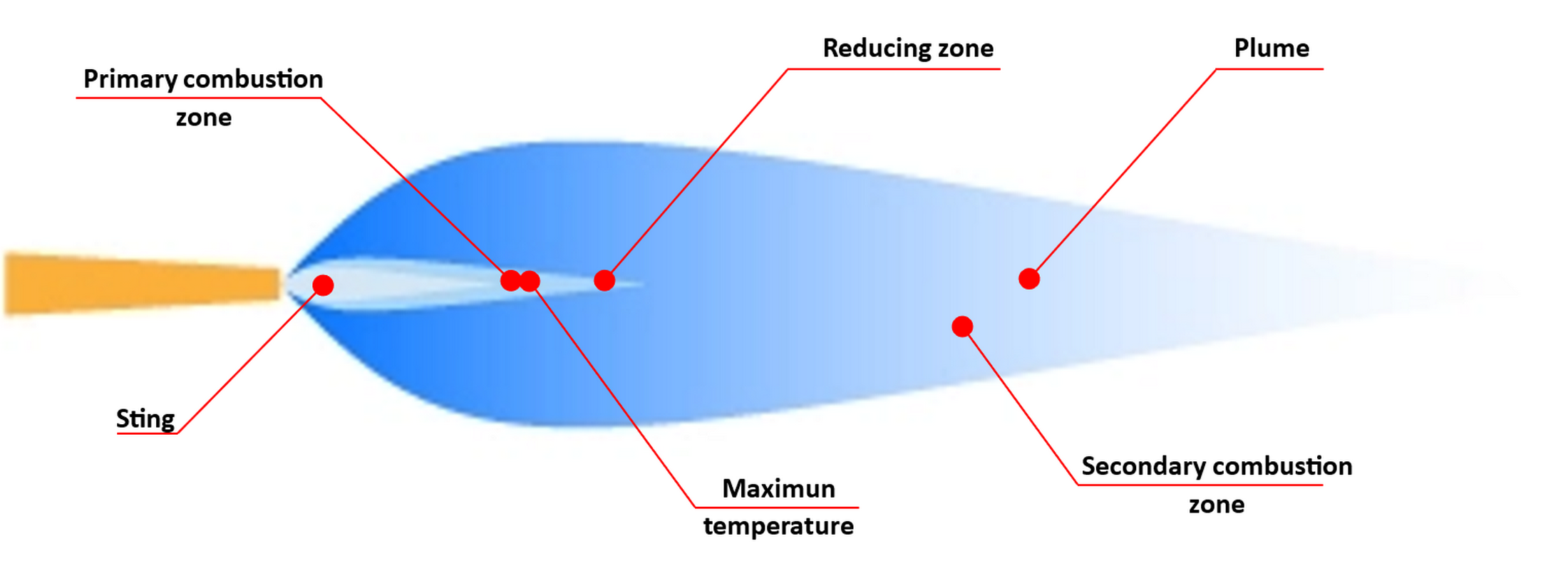

The Anatomy of a flame

The different flames

The carburizing flame

The carburizing flame uses excess fuel (acetylene, propane, natural gas, etc.).

Its sting takes on an almost cylindrical shape, although its contours are more irregular.Its color is bluish and relatively pale.

The carburizing flame is not suitable for welding steel, but rather aluminum, lead, zinc and cast iron.

The neutral flame

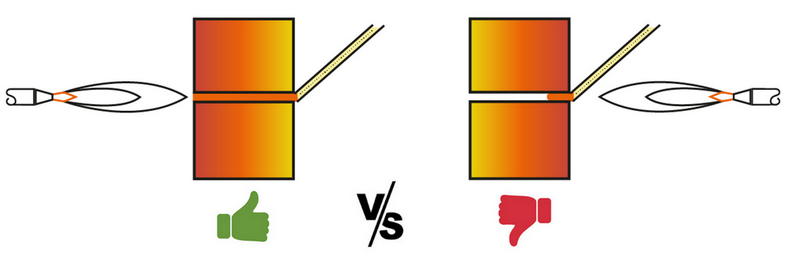

The neutral flame is traditionally used for brazing copper and steel. It is produced from a balanced mixture of the two gases.

Its cone is bright white. Its shape is perfectly clear when it emerges from the nozzle.

The oxidizing flame

The oxidizing flame is characterized by an excess of oxygen. Its plume and cone are shorter than those of a neutral flame. It produces a distinctive whistling sound, and its plume appears brighter.

The oxidizing flame is used for weld brazing and welding brass and bronze.

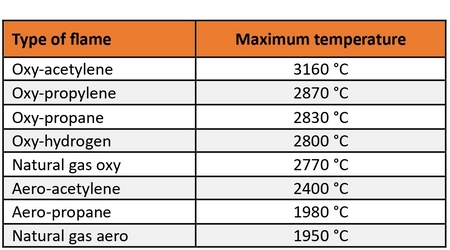

The main flame temperatures

Additional technical information on flame temperature

“It’s important to master the type of flame used during a brazing operation, as well as its settings.

Flame temperature has a direct impact on the materials to be brazed, the filler metal and the flux used.

• At the time of brazing, the flame guides the molten filler metal. This is known as heating guidance.

This is because the filler metal is attracted by the heat of the flame. In other words, once the filler metal has started to melt, it’s recommended to move the flame in “opposition” to the filler stick.

• Prolonged heating of a part can, depending on its design, alter or deteriorate its mechanical properties.

• The energy released by the flame distributes the flow over the surfaces to be cleaned/treated.